Shell and tube heat exchangers engineered

Pressure heat exchangers

the range of products:

AEM - BEM Series

AEM - BEM Series

FEATURES

High thermal efficiency heat exchanger with fixed tube bundle.

In case of particularly severe temperature conditions it should be necessary to install on the shell an expansion joint.

STANDARD APPLICATIONS

- To cool or heat water, oil, steam at low pressure, process fluids in general (petrochemical, chemical, pharmaceutics, textile industry).

The higher-fouling fluid should flow inside the tubes.

The materials usually employed are: carbon steel, stainless steel, copper alloys.

Different materials can be adopted on request. The design temperature and pressure are strictly connected to the service and meterials required. These heat exchangers can be designed and construed in accordance with the main intenational standards and codes (ASME, TEMA, VSR, EN 13445).

If applicable, heat exchangers can be CE - ∈ marked, in conformity with PED and/or ATEX Directives (97/23/CE - 94/9/CE).

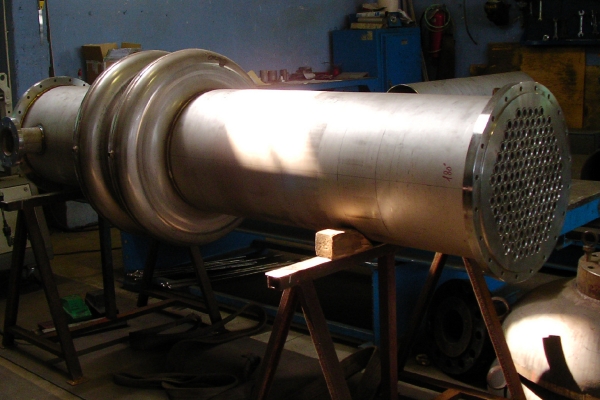

GALLERY

AEW - BEW Series

AEW - BEW Series

FEATURES

Heat exchanger with removable bundle and floating tube-sheet suitable to compensate the different expansion of the tubes and the shell.

The removable tube bundle allows easiness of cleaning also shell side.

STANDARD APPLICATIONS

- for liquid/liquid applications .

- to cool oil of turbine, hydraulic coupling, compressors.

GALLERY

AEU - BEU Series

AEU - BEU Series

FEATURES

Heat exchanger with "U" tubes usually with removable bundle.

This tipe of construction allows maximum expansion between tubes and shell and is particularly suitable to severe performance conditions with termal shocks.

It's use is limited to applications where the tube side fluid is not dirty.

STANDARD APPLICATIONS

- all processes with diathermic oil, steam, condensate, compressed gas.

The materials usually employed are: carbon steel, stainless steel, copper alloys.

Different materials can be adopted on request. The design temperature and pressure are strictly connected to the service and meterials required. These heat exchangers can be designed and construed in accordance with the main intenational standards and codes (ASME, TEMA, VSR, EN 13445).

If applicable, heat exchangers can be CE - ∈ marked, in conformity with PED and/or ATEX Directives (97/23/CE - 94/9/CE).

GALLERY

NEN Series

NEN Series

FEATURES

High thermal efficiency heat exchanger with fixed tube bundle.

In case of particularly severe temperature conditions it should be necessary to install on the shell an expansion joint.

The tube bundle is easily accessible for inspection or cleaning since it is not necessary to disconnect the piping.

STANDARD APPLICATIONS

- particularly suitable for applications with high fouling fluids.

- heat recovery from exhausted gas from diesel engines, gas and biogas.

- textile industry, coating machines, mud treatment.

The materials usually employed are: carbon steel, stainless steel, copper alloys.

Different materials can be adopted on request. The design temperature and pressure are strictly connected to the service and meterials required. These heat exchangers can be designed and construed in accordance with the main intenational standards and codes (ASME, TEMA, VSR, EN 13445).

If applicable, heat exchangers can be CE - ∈ marked, in conformity with PED and/or ATEX Directives (97/23/CE - 94/9/CE).

GALLERY

EM Series

EM Series

FEATURES

Heat exchanger with fixed tube-bundle.

1 passage countercurrent with high thermal efficiency.

It is directly line installed on the piping.

STANDARD APPLICATIONS

- to heat or cool compressed gases in general (air, methane, nitrogen, biogas...).

if necessary a demister can be installed down stream the heat exchanger.

The materials usually employed are: carbon steel, stainless steel, copper alloys.

Different materials can be adopted on request. The design temperature and pressure are strictly connected to the service and meterials required. These heat exchangers can be designed and construed in accordance with the main intenational standards and codes (ASME, TEMA, VSR, EN 13445).

If applicable, heat exchangers can be CE - ∈ marked, in conformity with PED and/or ATEX Directives (97/23/CE - 94/9/CE).

GALLERY

Serie BES - AES

BES - AES Series

FEATURES

This model has a floating head inside the exchanger with all its cover. The tube bundle is removable to facilitate frequent removal, inspection and cleaning. It is suitable for toxic or flammable fluids, but also for compressed air and gas as an inter-post chiller. The basic solution is 2, 4, 6 and 8 passages. The maximum thermal efficiency per unit exchange area is therefore guaranteed and the C tema requirements for refinery applications are met.